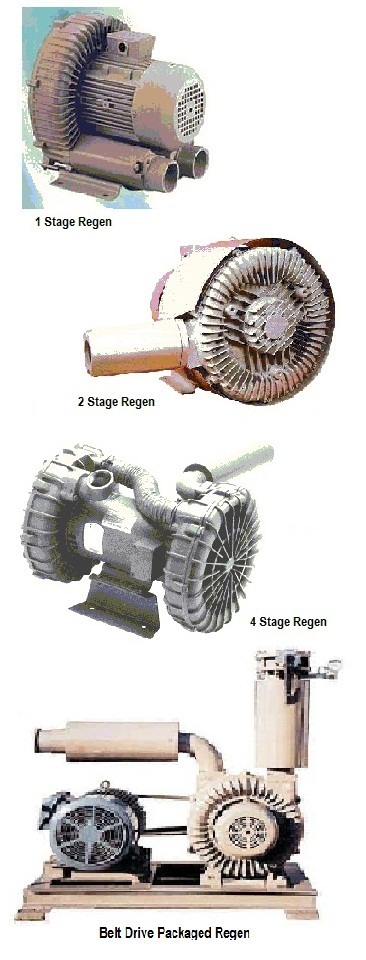

Regenerative Blowers

Regenerative Blowers, or Channel Blowers deliver up to 1,300 SCFM of uncontaminated flow at up to 8 PSIG pressure, and from 30” to 0” Hg vacuum . Typical applications include air conveying, refuse burning, instrument air, air dryer, air cushioning, tank agitation, sewage aeration, blister packing, liquid spraying, fuel atomizing, air knives, product curing, radon gas elimination, automatic bottling, vacuum holding, soil remediation, paper transport, scrap collection, powder recovery, gas sampling, thread holding, and all applications requiring medium pressure, or vacuum.

Regenerative, of Chanel Blowers are available with cast aluminum casing enclosing cast aluminum rotors. NPT threaded flange connection 1”, 1.5”, 2”, 2.5”, 3” and 4”, as well as metric threaded flange of type G are standard. Shaft sealing is provided by C-flange motor mount, or by sealed bearings.

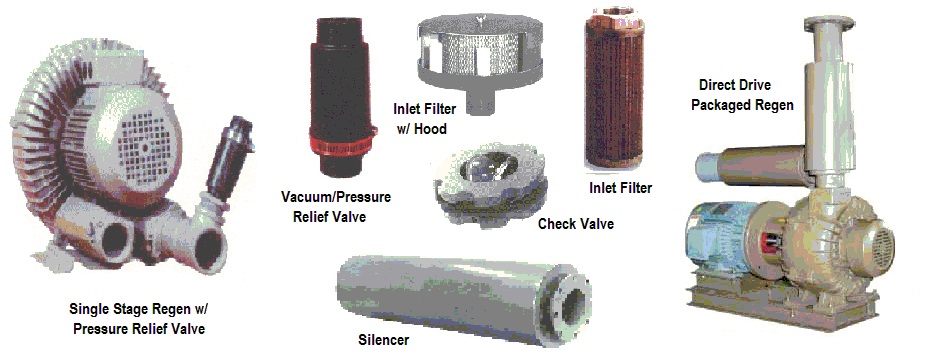

Regenerative Blower Packages are supplied on unitary base of standard or isolation type with RIS, or spring vibration isolators. Power transmission is implemented by V-Belt Drives complete with V-belts, adjustable or constant speed sheaves and pulleys, bushings, and motor slide bases; or by direct drive coupling. Motors are of High Efficiency design. OSHA Belt Guard and OSHA Coupling Guard are standard.

Expansion Joints, Flexible Connectors and Compression Couplings isolate Regenerative Blower to allow for thermal expansion and mis-alignment of piping.

Pressure / Vacuum Relief Safety Valves of VLR type are of spring loaded type kunkle valve. They set-up point of operation and bleed-off to prevent over-pressurization, or relief vacuum.

Inline Check Valves direct airflow or vacuum in one direction only. Flow Converters change direction of the flow by electronically, or pneumatically activated diverter.

Pressure/Vacuum Controls include differential pressure gauge up to 15 PSIG, vacuum gauge from 30” to 0” Hg, temperature gauge, gauge snubber to reduce pressure pulsation, and .25” pet-cock valve to isolate the gauge.

Regenerative Silencers are offered as inlet and discharge silencers with sound absorbing polyurethane elements. Additional auxiliary inlet and outlet silencers offer additional means of sound attenuation. Sound Enclosures are custom made based on application requirements.

Inlet Filters are offered with wire-mesh oil wetted (multi-wash), high efficiency ultra-synthetic (polyester, washable), or paper (thrown away)media. Controls included Differential Filter Pressure Gauge used as Filter Restriction Indicator. Filter casing is available as open flange design, hooded design, or combined filter-silencer assembly. In-line filters are custom.

Controls and drives: variable frequency drives (VFD), motor starters, are available in NEMA 1, NEMA 3R, NEMA 4 enclosure, as well as for x-proof applications.