The New York Blower Company

GFE FRP General-Purpose Fume Exhauster

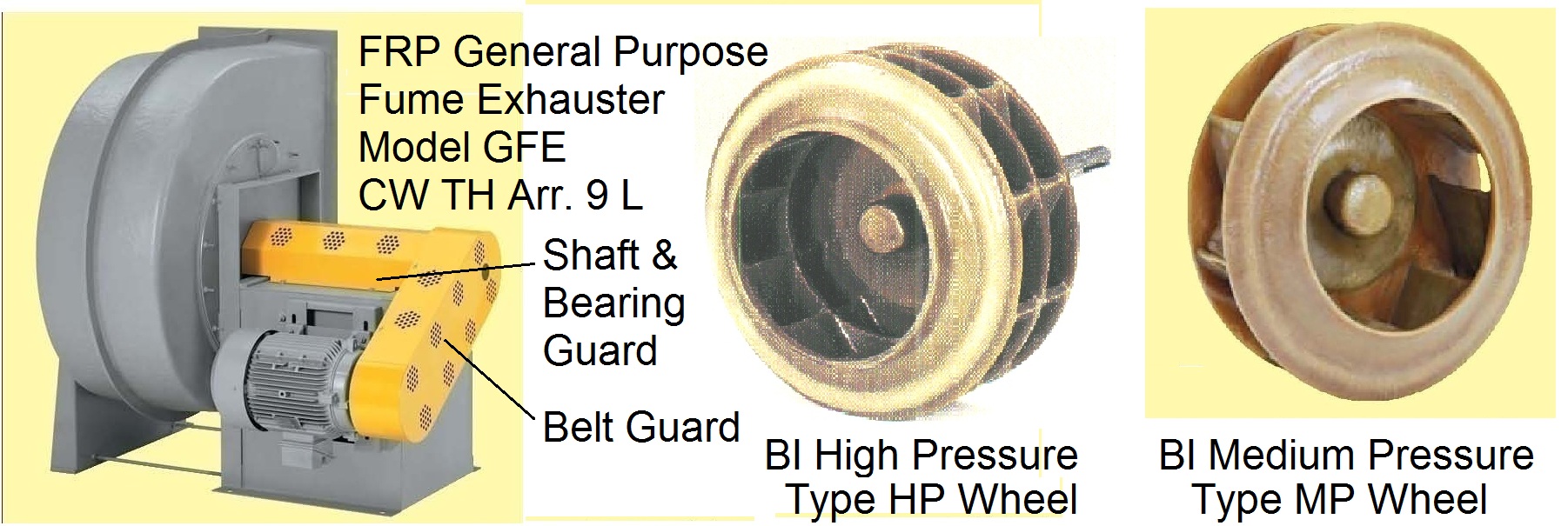

The New York Blower FRP General-Purpose Fume Exhauster [GFE] is designed so that all parts exposed to the airstream are constructed of corrosion-resistant fiberglass reinforced plastic. The GFE is suited to applications in the chemical, pulp and paper, wastewater-treatment, fertilizer, pharmaceutical, and metals industries.

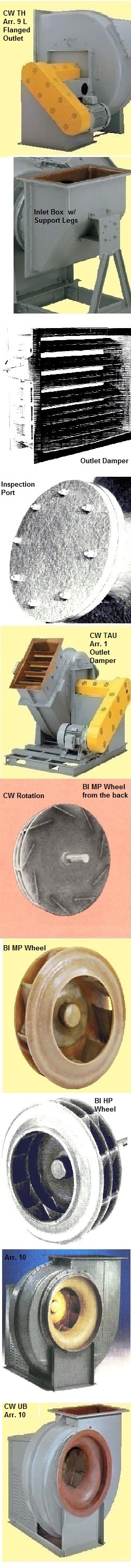

FRP GFE is available in ten sizes: 12”, 15”, 18”, 24”, 30”, 36”, 42”, 48”, 54” and 60” wheel diameters. Capacities to 73,000 CFM. Static pressures to 17”WG.Temperatures to 250°F. The flow-pressure curve is of non-overloading type.

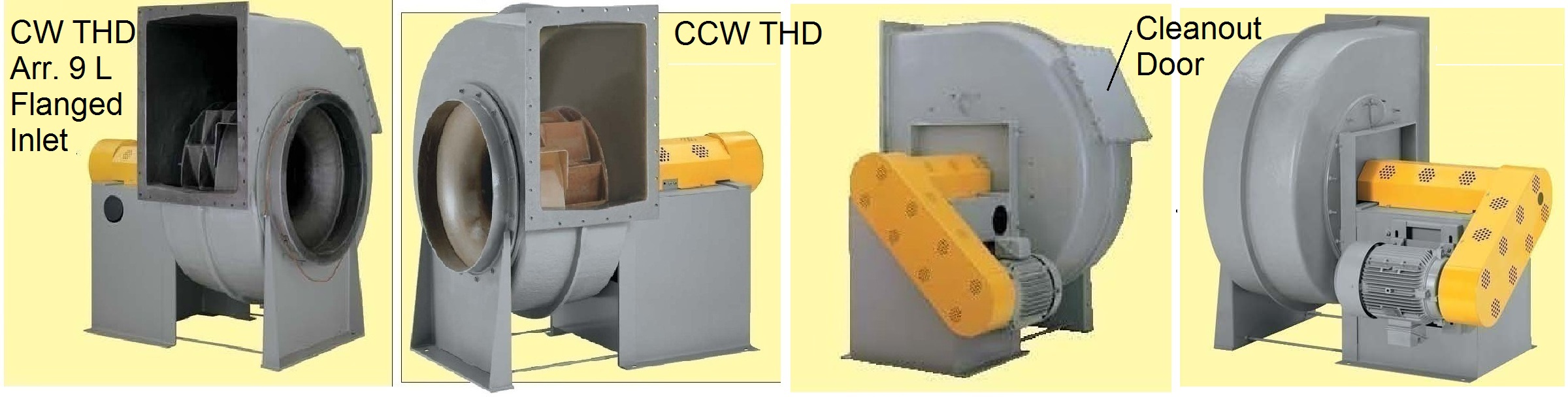

The New York Blower GFE FRP Blower is available in Arrangements 1, 8, 9, 9-E, 9-F, and 10.

FRP Blowers Construction Features: Housing is made of corrosion-resistant polyester resin. Flanged outlet for easy in-duct connection. Slip inlet suitable for flexible-sleeve inlet connection. All FRP fans are rotatable to five discharge positions. Lifting eyes on all fans for ease of handling. Welded steel base is constructed of heavy-gauge steel. Neoprene gasketing at all bolted FRP joints. Fan exterior is coated with gray epoxy enamel. Close-fit Teflon® shaft-hole closure limits the free exchange of gases through the shaft-hole opening. FRP Backward Inclined Medium pressure MP wheel and High Pressure HP wheel made of vinyl-ester resin, are dynamically balanced. After assembly, all FRP fans are given a final trim balance at the specified running speed. Sizes 181 and larger meet ASTM.

FRP Parallel-blade outlet damper—for flow control. All airstream parts are constructed of FRP.

FRP Flanged Outlet/Inlet Connections and Slip Inlet Connections a choice of flanged drilling in various bolt patterns, including ANSI 125/150, or ISO/DIN standard.

Unitary Bases available with spring or rubber-in-shear [R-I-S] isolators. Isolation rails are used to eliminate transmission of vibrations on arrangement 10 FRP blowers.

Threaded FRP Drain and PVC Plug 1” npt, at lowest point of housing scroll.

FRP Inspection Port and FRP Cleanout Access Door are gasketed and allow examination and provide access for cleaning and inspecting of the fan interior.

Positive screw adjustment motor base: two threaded rods provide easy motor platform/V-belt adjustment on Arrangement 10 fans.

Arrangement 10 weather cover/belt guard: provides motor and drive protection, and can be easily removed for inspection and maintenance. Louvered side panels provide ample motor ventilation. Safety equipment—belt guards and shaft and bearing guards are available for Arrangements 1, 9, 9-E, and 9-F fans, and coupling guards for Arrangement 8 fans.

FRP Inlet Box minimizes losses at blower inlet. Available with Access/Cleanout door, Inspection Port, FRP Drain and Plug, and FRP Inlet Box Damper.

Shaft Seals are available as Viton® elements in FRP casing. Type 316 SST sleeve covers shaft for use with seal. Teflon seal and Hastelloy C-276 sleeve are also available.

Surface Veil 1 or 2 layers for added protection against certain corrosives. Provides compliance to ASTM D 4167 for Sizes 181 and larger.

All-vinyl ester airstream provides additional protection from certain corrosives.

Spark Resistant Construction by Graphite impregnation provides control of static electricity. The gas-stream surfaces are grounded to the fan base.

FRP Narrow-width Construction is used to optimize the point of operation. Available on Sizes 181 and larger to 75% of full width on medium pressure fans and 67% on high pressure fans. Maximum safe wheel speed increases as width decreases.

FRP Blowers with Special Alloy Construction: airstream components, blower pedestal, guards, and unitary base can be constructed of a wide range of alternate alloys for corrosive applications: 950X/960X alloy; 980X alloy, aluminum, high strength aluminum 6061-T6 ; Monel, 304 stainless steel, 316 stainless steel, 2205 stainless steel, corten, etc.

FRP Blowers Protective Coatings: Cost-effective protective coatings under a variety of trade names are available to increase the fan’s resistance to adverse, corrosive environments.

FRP Blowers Drive components: motors, couplings, and v-belt drives, as well as a variety of preventive-maintenance products including vibration detectors, bearing-temperature detectors, and zero-speed switches are also available.

SAFETY ACCESSORIES: Safety accessories are available from nyb, but selection of the appropriate devices is the responsibility of the system-designer who is familiar with the particular installation, or application, and can provide for guards for all exposed moving parts as well as protection from access to high-velocity airstreams. Users and/or installers should read “Recommended Safety Practices for Air Moving Devices” as published by the Air Movement and Control Association International, Arlington Heights, Illinois.

AMCA SEAL and LABELS: The New York Blower Company certifies that the FRP Fume Exhausters shown herein are licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and comply with the requirements of the AMCA Certified Ratings Program.