Chicago Blower Corporation

Chicago Blower Presure Blowers

Design 15 & Design 53 Pressure Blowers>

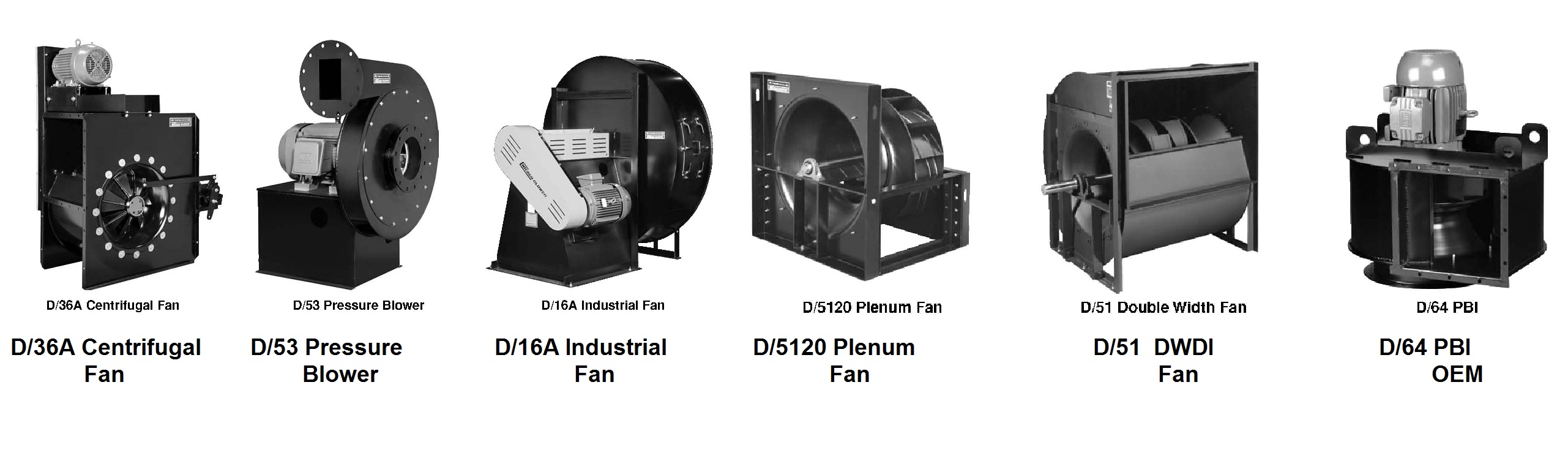

Chicago Blower Design 15 and Design 53 Pressure Blowers are supplied with heavy gauge housings and pedestals. Housings and pedestals are fabricated of heavy gauge steel, continuously welded and rigidly braced. They will stand up to rigors of strenuous duty, delivering smooth vibration-free performance. Removable inlet cover plate provides access to the wheel.

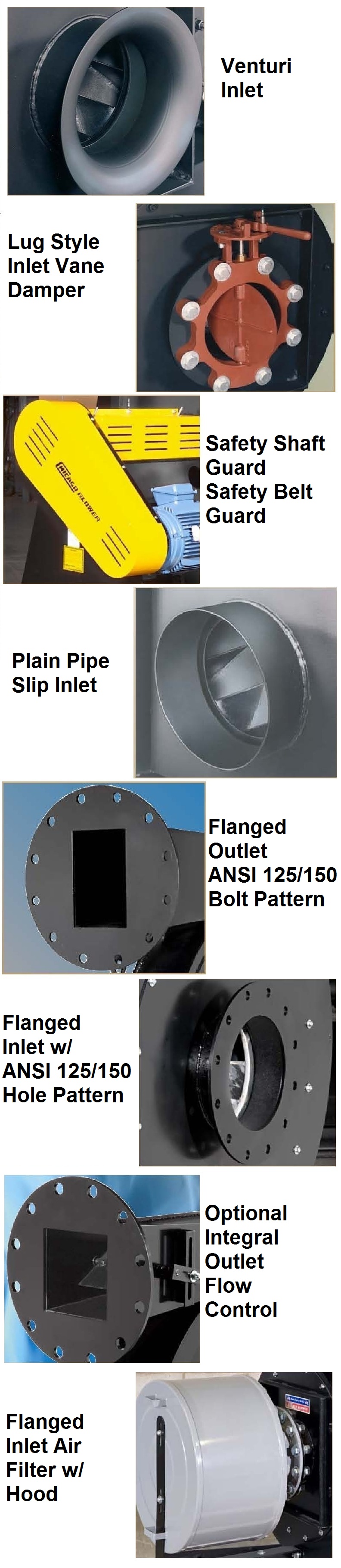

Design 15 and Design 53 Pressure Blowers are supplied with standard slip-fit inlet which facilitatets field mounting of either sleeves or flexible connectors. Flanged Inlets, or Venturi inlets are optional.

Shaft & Bearings used for Design 15 & Design 53 Pressure Blowers are oversized for a critical speed at least b1.35 times maximum RPM of teh blower assembly. Bearings are heavy, industrial duty ball, or roller in cast iron pillow blocks.

Design 15 and Design 53 Pressure Blowers utilize lightweight wheels of exclusive constant velocity design, made of aluminum alloy, which alows for sustantial load reducing on teh motor-drive components. The blades are positioned with precision fixtures and gas netal arc welded to teh spun aluminum side plates. The wheels are mopunted to the shaft with taperlock bushings.

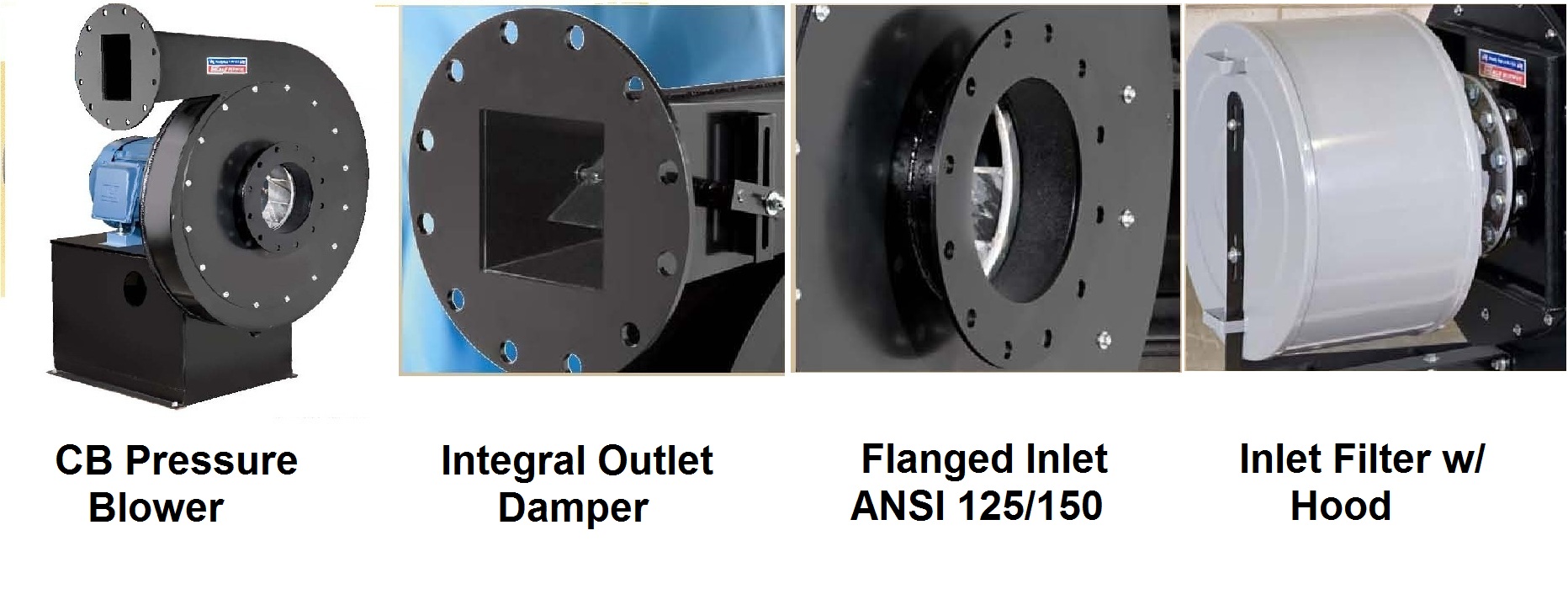

Flanged Outlets used on design 15 and Design 53 Pressure Blowers are standard, supplied with ANSI Class 125/150 pipe flange bolt holes and bolt circle to provide easy connection to flanged pipe. Outlets are continuously welded to the housing.

Inlet Filters for design 15 and Design 53 Pressure Blowers and Exhausters are available in two types paer and reusable wire mesh. Filter consists of an element, a base welded directly on teh fan inlet, and a lid held in place with wing nuts. Rain hoods and filter silencers are available.

Butterfly Valve Gate used on Design 15 and Design 53 Pressure Blowers is intended to fine tune performance or to vary the flow. The standard lug type mounts to the flanged inlet/outlet. A wafer type valve mounts between two matchiong flanges. Both types are controlled manually or with various actuators.

Outlet Slip Tube is bolted to the outlet flange of a standard schedule 40 pipe. Slip tubes with dimesnions for flexible hoses are available.

Flex-Sleeve is a specially designed rubber sleeve which forms a flexible connection to help to isolate the fan from vibrations elsewhere in the system. The 6" long sleeve is backed with a tough corded rubber cover held with stainless steel clamps.

Vibration Pads are made of low density cork and are designed to be mountyed between the fan pedestal and teh floor to reduce transmission opf vibrations.

Inlet Guard is fabricated of concentric rings and mounts on inlet venturi.

Venturi Inlet provides smooth flow into the wheel for optimum performance. Inlet venturi is required on open inlet blowers to meet catalog performance.

Flanged Inlet simplifies connection to a flanged piping. Flanges have ANSI Class 125/150 pipe flange bolt holes and bolt circle dimensions. The inlet flange is continuously welded to the inlet.

Guards & Extended Fittings Both options can be furnished on Arrangemnt 1, 8, and 9, to enclose shaft, bearings and couplings. The extended grease fittings permit bearing lubrication without removing the guards.

Shaft Seals reduce leakage around teh shaft where it passes through the housing. Shaft seals should not be considered as gas tight.

Discharge Elbows are needed on some downblast discharge models to allow discharge flange to clear the pedestal.

Special coatings and alloys used on Design 15 and Design 53 Pressure Blowers are intended for corrosive applications.